Our aim is to contribute towards a better and cleaner world.

To establish our goals, we use the SDG‘s as a general guide

line and promote the strategy for sustainability (toxic-free EU environment) .

We specialize in delivering the best available (chemical-free) solutions for:

- Treatment of wet surfaces and reducing CFU’s in:

- piping systems

- above-and underground buffer tanks

- cooling towers

- heat exchangers

- rainwater collection basins

- Fighting algae (incl. blue-algae or cyanobacteria) in ponds and recreational waterbodies

- Prevention of biofouling on submerged marine structures.

- Cleaning semi-wet or periodically dry surfaces.

- HVAC applications (atmospheric air cleaning of commercial and industrial buildings).

- Aerating water masses with (nano)bubbles to fight aquatic hypoxia and to improve the efficiency of water recycling installations

Our emphasis is :

- on the use of environmental acceptable techniques, methods and products

- to avoid dismantling and installation downtime (optimize MTBF)

- to act, if possible, both preventive and curative

- to reduce or completely avoid the use of chemicals like biocides, descalants or other inhibitors

In general, contamination usually comes down to the formation of dynamic communities of surface-attached multi-species forming a “biofilm”.

All liquids contain free floating (planktonic) micro-organisms and have the tendency to initiate bio-fouling on their contact surfaces. What follows is the formation of a biofilm that again will attract and accumulate more contaminants.

Until recently, biofouling could only be removed manually or with (harmful) surface acting agents such as disinfectants or biocides.

Now we have safer and more environmentally friendly methods like ultrasound, catalysts (NOA’s) and the application of “healthy” or “positive” micro-organisms.

Our methods have the advantage of being :

- able to clean thoroughly and even into cracks and pores. They also bypass the survival strategies of certain bacteria (the so called habituation and sensory adaptation).

- used as CIP (Cleaning In Place) thus reducing downtime and disassembling of installations.

Other advantages :

- very low power consumption (with ultrasound and catalysts)

- the consumption of chemicals can be reduced or sometimes completely eliminated

- systems can be custom build for a variety of applications

- works preventive and in many cases also curative

- ultrasound technology works acoustic, so no radiation or electromagnetic waves are used

- catalysts (NOA’s) work upon restructuring the water molecules and restoring the natural balance (hydration shells).

- there is only little maintenance required

- the organoleptic properties of the treated liquid are in most cases not altered (texture, color and taste). Which is of great advantage in the food industry

- many studies and references are available, mail us for relevant publications.

“Humans, animals and their environment request a change in mentality with regards to the use of biocides”

Biofilms are nutrient-rich (often slimy) layers and grow virtually everywhere and in almost any environment where there is a combination of :

- a liquid or moist environment

- nutrients

- a man-made or natural surface (the substrate)

In addition, optimal acidity and temperatures + stagnant water will even accelerate their growth.

For example, temperatures between 20 and 45°C already promote legionella growth while they proliferate best at temperatures between 32 and 35°C.

In particular, dead-legs or end pipes of (emergency drench) showers and sprinkler installations are vulnerable for this bacterial build-up.

Contrary to what many people think, even electropolished stainless steel surfaces can attract biofilm formation.

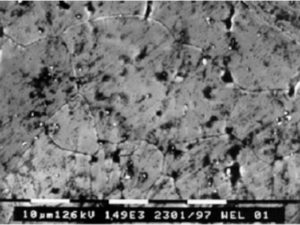

Picture Right : Stainless steel surface with pore contamination,A=1500x ( Source Dockweiler Nederland b.v. )

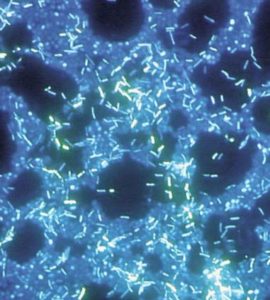

Picture left : Polymicrobic biofilm grown on a stainless steel surface in a laboratory potable water biofilm reactor for 14 days, then stained and examined by epifluorescence microscopy. (source CDC,2002)

in a laboratory potable water biofilm reactor for 14 days, then stained and examined by epifluorescence microscopy. (source CDC,2002)

Even desalinated, demineralized and UPW (Ultra Pure Water) can trigger biofilm formation due to the presence of oligotrophs. (organism that can live in an environment that offers very low levels of nutrients)

On this website we concentrate on the applications where bacteria and/or perseverant biofilm formation (like CaCO3) are not desired due to economic, functional, esthetic or health reasons.

(causing diseases, undesired smell, clogging, slime formation, algal bloom, reduced heat transfer, etc…)

We offer both off-the-shelf products as well as customized systems with combined techniques, whereby the efficiency can be measured over time to optimize the results required.