MOL®LIK – a technical proven catalytic water treatment technology – is a biocide-free technology that reduces the risk of fouling, scaling and corrosion on downstream surfaces, even at long distances. With this technology, there are entire cooling systems of power plants operated completely free of any biocide – with less than 2 kg of the special catalyst.

After showing reliable results on areas with quite stable water quality, like tap, cooling and process water treatment, catalytic water treatment was tested in challenging areas of industrial wastewater within the INSPIRE WATER project. Within this project, the scope was to investigate the potential for improving membrane performance with catalytic water treatment in the field of effluent water reuse.

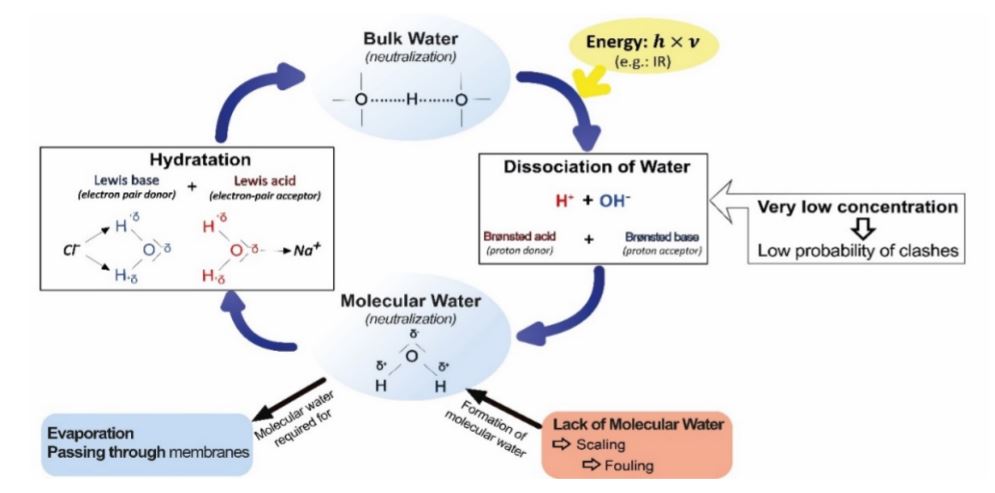

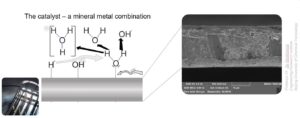

Working principle:

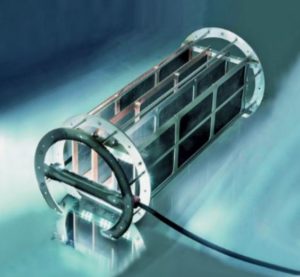

The core element of the MOL®LIK-technology is a proprietary ultra- thin metal catalyst foil, made of nickel, chromium and iron.These catalysts are speeding up the formation of solvatation shells. The result is that more hydration shells are formed and therefore the equilibrium between bulkwater and molecular water is reached faster. The faster these shells are prepared, the less clusters are formed and the better flux is achieved. As a side effect, the risk of deposits formation and biofouling is greatly minimized.